World class biochar production facilities made in Finland

Remove CO2 by converting waste biomass into biochar

Industry-level biochar production technology

Suitable for biogas, pyrolysis oil, and clean energy production

Clean

Biomass is carbonized in 600-700 degrees celsius, pyrolysis gas combusted at 1000 degrees celsius with minimal emissions.

Efficient

Excess energy from the plant can be used for heating, steam or other purposes.

Adjustable

High-precision process optimization capabilities enable the use of various feed stocks. Controlled pyrolysis process enables efficient biochar production.

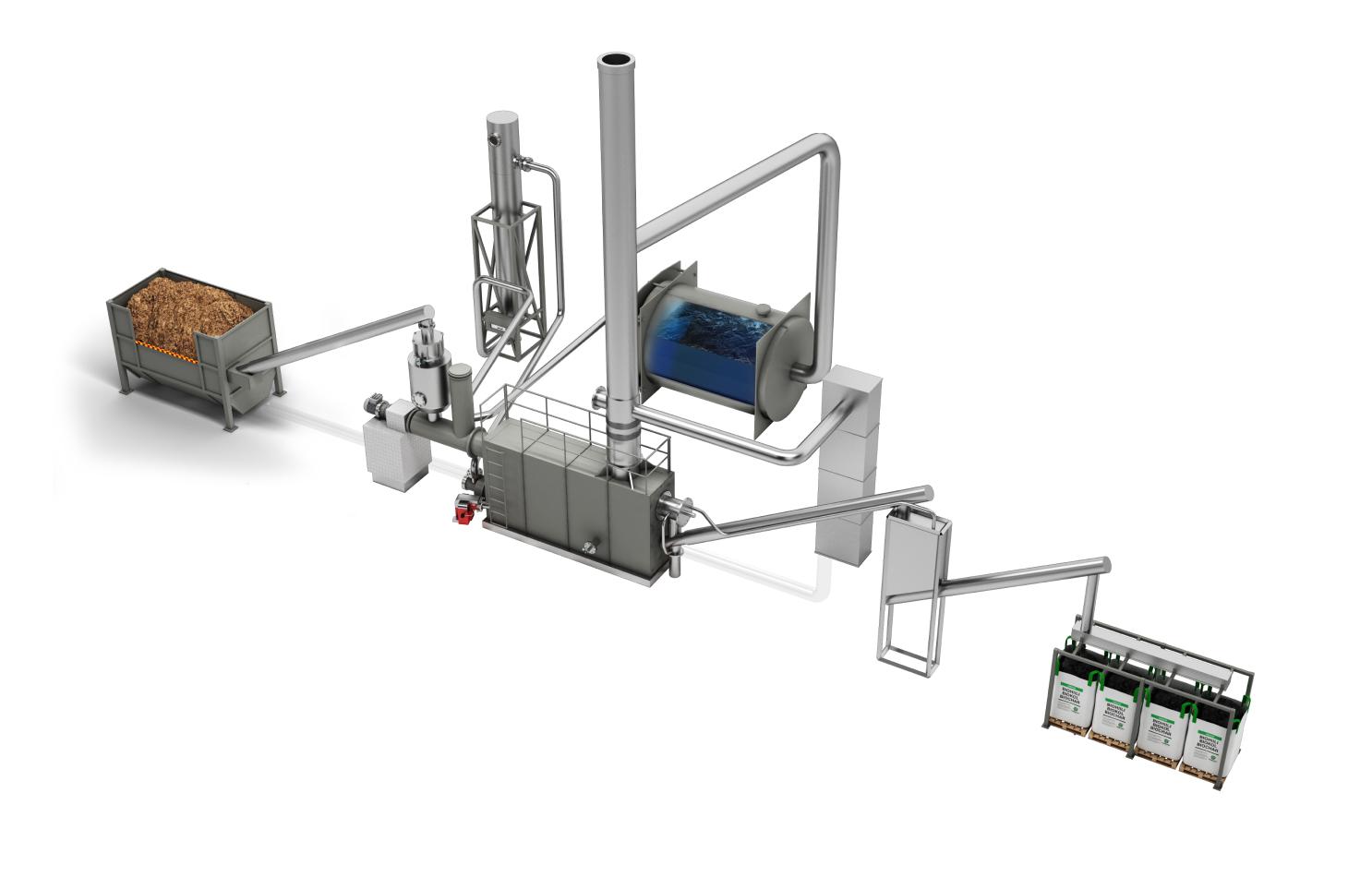

Unique, state-of-art, turnkey solution for biochar and bio-energy co-production.

Carbofex demo plant

Cutting-edge pyrolysis technology

Our demo plant has been in operation since 2017. This specific unit carbonizes up to 500 kg of wood chips per hour, turning it into 140 kg of biochar and 1MW clean energy power.

With an optional electrostatic oil separator, the system can produce 100 liters of high-quality pyrolysis oil.

The facility can produce 1000 tons of biochar and 600 tons of oil per year, and up to 8000MWh clean energy as part of a municipal heating network.

INPUT

• 3500 t biomass

SUITABLE RAW MATERIALS

• waste wood chip and pellet

• nut hull / husk

• straw pellet

• olive pits, olive cake

• coconut shell

• date pits, palm kernels

• lignin pellets

Biochar is the real black gold

Biochar turns carbon from potential climate disaster into an environmental solution and profit.

Biochar helps to create more fertile soil. It increases soil productivity and improves crop yields while effectively purifying runoff water.

Wellover 90% carbon content makes Carbofex Biochar excellent climate and environment friendly raw material option for multiple industrial use cases.

Carbofex Biochar is approved for Agro Organic quality class of the EBC, suitable for soil improvement use without restrictions. It is produced in Finland from domestically sourced, PEFC-certified raw materials. Carbofex Biochar is approved for organic production by the Finnish Food Authority.

We supply Biochar for wholesale and large use case customers globally. For quote contact info@carbofex.fi

About pyrolysis

About our biochar

Carbofex pyrolysis technology

The continuous pyrolysis unit utilizes biomass to high degree. The unique, controlled pyrolysis technique allows usage of variety of raw material and precisely controlled carbonisation.

Temperature and the residence time can be accurately adjusted so the resulting biochar is of uniform quality.

Carbofex biochar

Carbofex Biochar is pure and of high quality. It clears by large marginal all limit values designated to biochar. It is approved for ORGANIC food production and produced of PEFC certified feed stock.

Carbofex biochar is certified to Agro Organic classification.

We are one of the biggest EBC-certified biochar producers in Europe.

EBC-certification ensures that the feedstock and production are sustainable and the biochar high quality.

Biochar natural is multi purpose biochar product, it is treated only with water, it contains no additives and is free of chemicals. Carbofex biochar has large surface area of +364 m2/g, high carbon content 92% and pyrolysis temperature of 650-700C.

Biochar natural is a vegetal carbon and is suitable for: substrate, soil improvement and filtering applications. It is EU-approved for animal feed additive and for stall-, cattle shed-, piggery-, henhouse floor desiccator additive and gas/odour management.

Economics of biochar

Biochar

1,001 tons

=

2,002,000 €

Clean energy

8,001 MWh

=

400,015 €

CO2 removals (CO2 eq)

3,220 tons

=

400,015 €

Global impact

Our unique, proven technology uses pyrolysis to convert short-cycle carbon stored in biomass as CO2 into mineralized long-cycle carbon in the form of biochar. Biochar has many studied uses for positive impacts for environment and society.

Amount of CO2 captured since 2017

9,800,000

kilograms

Equals the carbon footprint of

2,040

average global citizens

Carbon removal is certified by:

Biochar in action

Convert unutilized biomass and organic waste into valuable biochar with pyrolysis technology. The process removes CO2 from atmospheric circulation and generates clean energy, among several other benefits.

100% of Stockholm´s parks grow on fertile and clean biochar soil.

6,500 tonnes of organic waste becomes a growing ground for plants in the Swedish capital. The project will deliver revenue on the city’s investment in eight years, estimated at approximately 850,000 EUR.

Global loss of fertile land to be replaced with biochar

4,000,000,000

tonnes

94 % clean carbon used in semiconductor, battery, and environmental filtering technology.

Replacing fossil materials and bringing essential solutions to developing nations and industries, there are over 50 practical uses for biochar.

Number of scientific studies to support the use of biochar since 2007

7,369

studies

Europes largest pyrolysis plant - sells out production for over a year in advance.

80 % of the product is exported overseas. The rapidly growing market of biochar products is estimated to reach a total value of over $3 billion by 2025.

The estimated value of the biochar market in 2025

3,000,000,000

dollars

Have you ever wondered how agricultural waste can be transformed into a powerful tool for sustainability and climate action?

Watch the video below!

Contact Us

Carbofex Network

Don´t just take our word for it

We work closely with many organizations that evaluate and certify our facilities, products, and impact.

Carbofex team

When other kids still played with toys, we played with biomass, made char, and developed the foundations of what Carbofex is today – the real clean carbon maker.

PRODUCT MANAGEMENT

Kim Lehiö

CHAIRMAN AND CO-FOUNDER

Veikko Kantero

CEO

Jussi Lemiläinen

CFO

Janne Kantero

Mauri Ranta

SALES AND OPERATIONS MANAGEMENT

Anna Yrjönen

OUR WORK TOWARDS

Shared global targets

The United Nations’ Sustainable Development Goals set out targets for improving the sustainability of our planet and the health and well-being of its inhabitants.

Carbofex helps to work towards the achievement of these goals by improving soil fertility, desalinating water, producing renewable energy, reducing atmospheric CO2, and combating desertification and deforestation.